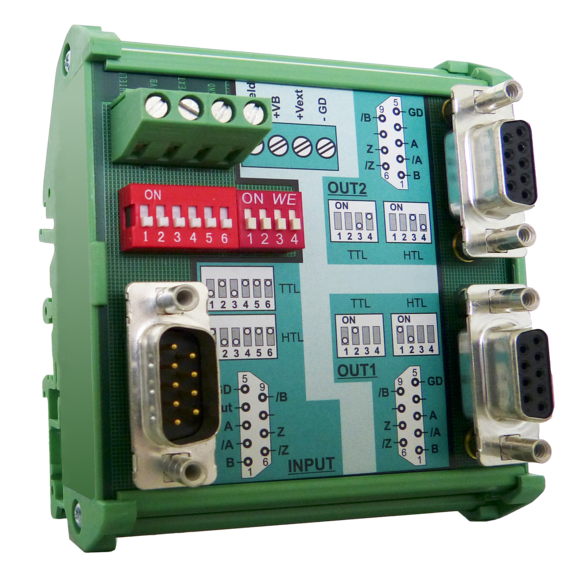

IF09, Impulse Splitter and Converter for Incremental Encoders

IF09 is a versatile and low-cost device designed to split AB0 or AB0 /AB0 signals supplied from an incremental encoder (either TTL / RS-422 or HTL) and provide them through two outputs that can be programmed individually to either TTL or HTL.

- 1 input for AB0 or AB0 /AB0 signals from a TTL / RS-422 or HTL encoder

- 2 AB0 /AB0 TTL (5V) or HTL (10 … 30V) independent outputs

- Input frequency 750 kHz (TTL) o 350 kHz (HTL)

- Power supply +5Vdc or +10 … +30Vdc

IF09 is an impulse splitter and converter designed to divide the input signals from a single incremental encoder into two independent channels at output. It is possible to connect at input either a TTL / RS-422 encoder (+5Vdc) or an HTL encoder (+10 … 30Vdc); the unit accepts single-ended signals or differential signals in any industrial impulse format and level: single-ended HTL, RS-422, TTL-differential, HTL-differential. The two outputs can be programmed individually and always provide all signals AB0 /AB0, even when the inverted signals are not available at input.

The output signal level can be selected to +5V or to +10 ... +30V by means of the DIP switch. So for example we can connect a single-ended HTL encoder with +10 … +30Vdc power supply and set the first output OUT1 to AB0 HTL and +10 … +30V level and the second output OUT2 to AB0 /AB0 TTL-differential and +5V level. In this case the device operates as a splitter and as a converter at the same time.The max. input frequency can be 750 kHz for TTL signals and 350 kHz for HTL signals.

IF09 also provides an auxiliary voltage output +5Vdc to supply the encoder.

The enclosure has a very small footprint and offers 35 mm top hat DIN rail mounting according to EN 60715.

Incremental encoders with high resolution and accuracy

I58, CK58, I65/IT65, and I58SK series incremental encoders can be equipped with high resolution and high accuracy glass disks and electronics as an alternative to unbreakable disks for lower resolution and standard accuracy.

In this configuration they offer higher resolution up to 10,000 PPR and higher signal precision for use in high-end applications.

• Incremental encoders with digital outputs (NPN, PNP, HTL, TTL, Universal)

• Glass disk version and unbreakable disk version

• High resolution up to 10,000 PPR and high accuracy

• IT65 with US size square flange

• I58SK stainless steel version

Digital versions (NPN o.c., PNP o.c., Push-Pull, Line Driver and Universal output circuits) are now available also with new glass disks and electronics which allow to reach higher resolution up to 10,000 PPR and higher accuracy. They can be mounted as an alternative to the standard unbreakable disks.

So the series are offered in two options (see the product datasheet and the order code):

• encoder with unbreakable disk, resolution up to 5,000 PPR and standard accuracy: it is intended for use in normal industrial applications;

• encoder with glass disk, designed for high resolution up to 10,000 PPR and high accuracy demands; it is aimed at advanced automation applications; this encoder is distinguished by the letter K following the resolution value in the order code (i.e., “5000” = 5,000 PPR, standard version; “5K” = 5,000 PPR, high accuracy version, see the datasheet).

I58 and I58S are industrial encoders with Ø 58 mm (Ø 2.283”) servo or clamp flange and solid shaft. The shaft diameter ranges from 6 to 12 mm (0.24” to 0.47”).

CK58, CK59, and CK60 are the 14-mm and 15-mm diameter (0.55” and 0.59”) hollow shaft corresponding versions.

I65 and IT65 offer a more rugged structure that enables high shaft load and IP66 protection rate. IT65 further provides US size square flange (4-bolt 2.063" bolt center-to-center square flange).

I58SK is the AISI 303 stainless steel incremental encoder for use in demanding food-grade applications: it offers stainless steel structure, 58-mm clamp flange, 6 to 12 mm diameter (0.24” to 0.47”) solid shaft, specific hygienic design and features.

The max. counting frequency is up to 300 kHz in all encoders while the range of the extended operating temperature -40°C +100°C (-40°F +212°F) can be required as an optional. Cable and connector outputs are both available.

LD series multi-function displays go touch screen

Lika Electronic widens its range of LD multi-function process indicators and introduces four new models designed to interface analogue absolute encoders, SSI absolute encoders and HTL/TTL incremental encoders as well as NPN/PNP/NAMUR sensors.

The new range reaches a higher level in usability and versatility. They feature a totally new touch screen and 7-segment graphic display with a complete set of plain text, symbols and units. The LED display is bright and provides high contrast readability and also allows the background light to turn red, green or yellow in the event of the set occurrences such as when the threshold limits are exceeded. The combination of plain text and touch screen functions makes the parametrization very user-friendly and intuitive. The protection rate is IP65. The new range is offered in four models:

• LD210 is designed to interface current/voltage analogue encoders;

• LD220 is designed to interface SSI single- & multiturn encoders;

• LD350 / LD355 are designed to interface HTL/TTL encoders and NPN/PNP/NAMUR sensors.

LD350 / LD355 process indicators are designed to support many operating modes such as position indicator, tachometer and speed indicator, frequency / RPM indicator, process meter, counter, timer, stopwatch, etc. The input frequency can be up to 1 MHz.

They also implement the counting direction and linearization functions.