new2022

Advantages of Installing Draw-Wire Encoders

Draw-wire encoders are a little-known type of measuring system. So they are occasionally taken into consideration when it comes to designing a new solution for industrial applications.

Yet there are a number of good reasons why designers should appreciate their functional characteristics.

In some cases they can be the most effective and reliable answer to their measuring needs.

• Measuring lengths from 300 mm (0.984 ft), 1 m (3.28 ft), 2 m (6.56 ft), 5 m (16.4 ft),

10 m (32.8 ft), and longer, up to 50 m (164 ft)

• Any type of encoder can be integrated: incremental, absolute, fieldbus, Ethernet, analogue

(including potentiometer), ATEX, special models for individual applications

• Resolution down to 0.01 mm / 10 µm

• Speed up to 10 m per second / 32.8 ft per second

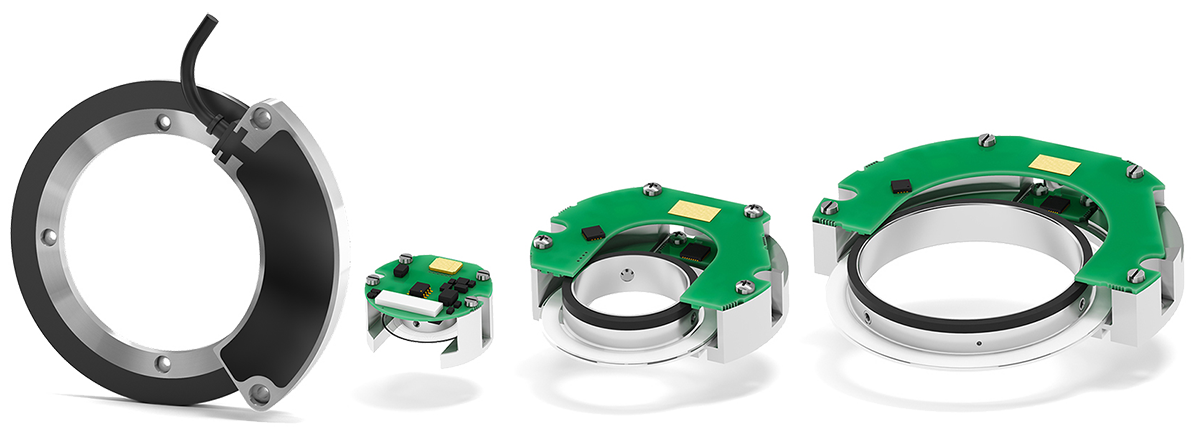

Magnetic Modular Encoders

Lika Electronic designs and manufactures a comprehensive range of incremental and absolute magnetic modular encoders in a huge variety of mechanical design types and electrical interface options. They can be customized according to needs and paired with magnetic rings, segmented rings, arcs, curved structures, or also with magnetic hubs.

Magnetic modular encoders are basically available in two construction types: housed encoders and frameless encoders. Housed magnetic modular encoders are made up of a readhead equipped with an MR sensing element and an active measurement scale, namely a coded magnetic ring.

Lika Lab: custom made standard

Since its inception Lika Electronic has successfully developed custom encoders that make it easier for the customers to fit the right encoder into non-standard applications. Today Lika has the knowledge, the skill, and the expertise to satisfy specific design and engineering criteria while cutting off time-to-market and production time and cost. At the present time 56% of Lika's yearly turnover is generated by standard products while 44% is generated by custom products.

More than 300 special and custom products are currently active in production.

To support special projects and custom encoder products to be developed in close cooperation with our customers in a targeted manner, we formed Lika Lab. Lika Lab is the R&D business unit with a broad range of capabilities in design, prototype fabrication, and testing, focused on individual customer needs and rapidly evolving market requirements.

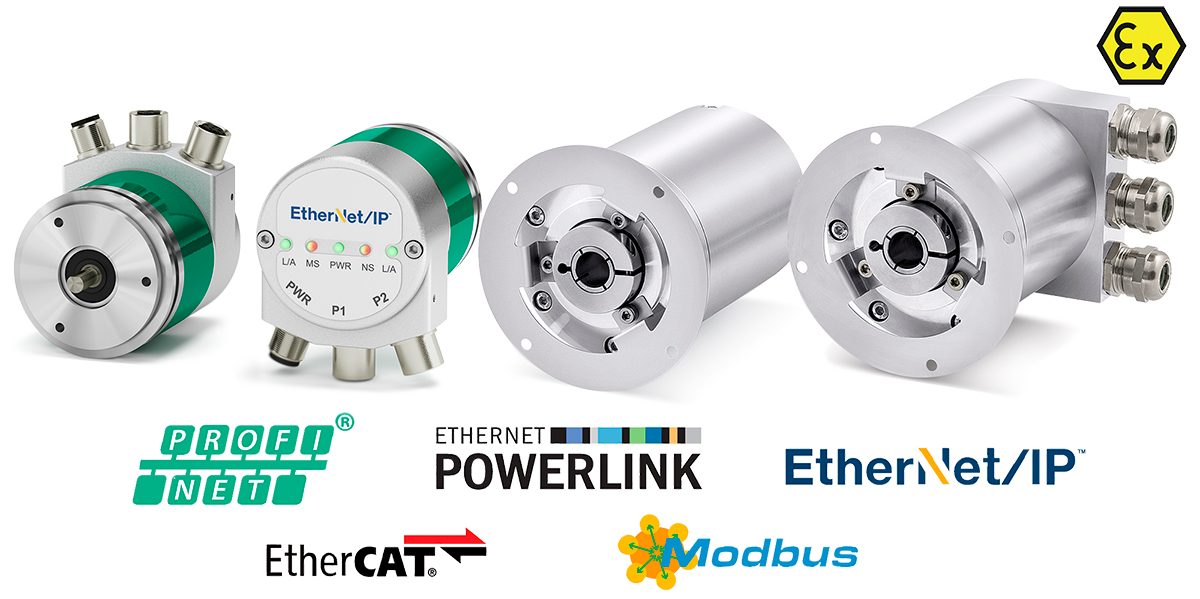

Absolute rotary encoders with Ethernet & Fieldbus interfaces

Lika Electronic offers a comprehensive range of absolute rotary encoders with Ethernet interfaces (Profinet, EtherNet/IP, EtherCAT, POWERLINK, Modbus TCP) as well as with fieldbus serial interfaces (Profibus, CANopen, Modbus RTU, DeviceNet). Lika's portfolio will be enriched also by new models equipped with Ethernet technology based CC-Link IE interface soon.

All Ethernet and fieldbus encoders fully comply with the specifications of each protocol and profile both in the hardware and in the software. They integrate the complete set of configuration parameters (position and velocity readout, scaling, preset, code sequence, …) and provide advanced diagnostic functions, even via integrated web server.

M12 connectors can be available in both radial and axial configurations to meet various installation requirements.

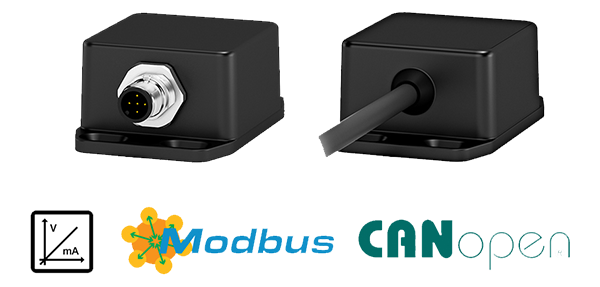

Accurate and reliable inclinometers for critical applications

Lika Electronic's IX series inclinometers can be equipped with analogue, CANopen, and Modbus interfaces, are rugged and accurate, and always provide reliable measurement of inclination even in critical environments such as in construction vehicles, agricultural machinery, mobile cranes, forklifts, bucket trucks.

• IXA: 1-axis (0°÷360°) and 2-axis (±10°, ±30°, ±60°) current and voltage analogue inclinometer

• IXAR: redundant analogue version with duplicated electronics

• IXB / IXC: 1-axis (0°÷360°, ±180°) and 2-axis (±5° to ±60°) programmable CANopen inclinometer

• IXM: 1-axis (0°÷360°, ±180°) and 2-axis (±5° to ±60°) programmable Modbus inclinometer

• High resolution down to 0.001°, high accuracy down to ±0.05°

• Rugged housing for reliable operation in harsh environments

More information

LD series multi-function displays with touch screen

The range of LD multi-function process indicators from Lika Electronic includes six models designed to interface analogue absolute encoders (LD210 model), SSI absolute encoders (LD220 model) and HTL/TTL incremental encoders as well as NPN/PNP/NAMUR/TRI-STATE sensors (LD350, LD355, LD360, and LD365 models).

• Multi-function process indicators with touch screen and three-color display

• LD210 is designed to interface current/voltage analogue encoders

• LD220 is designed to interface SSI single- & multiturn encoders

• LD350, LD355, LD360, and LD365 are designed to interface HTL/TTL encoders and

NPN/PNP/NAMUR/TRI-STATE sensors

LD displays can be used for all applications that require to measure, count, display, and control linear and rotary positions, angles, linear and rotary speeds, cycles, frequencies, flows, etc.

Among their numerous applications are for instance: Food industry, Packaging lines, Handling systems, Bending machines, Continuous material systems (e.g. extrusion machines), Conveyor belts, Cutting and winding applications, Cranes, Amusement parks, and many others.

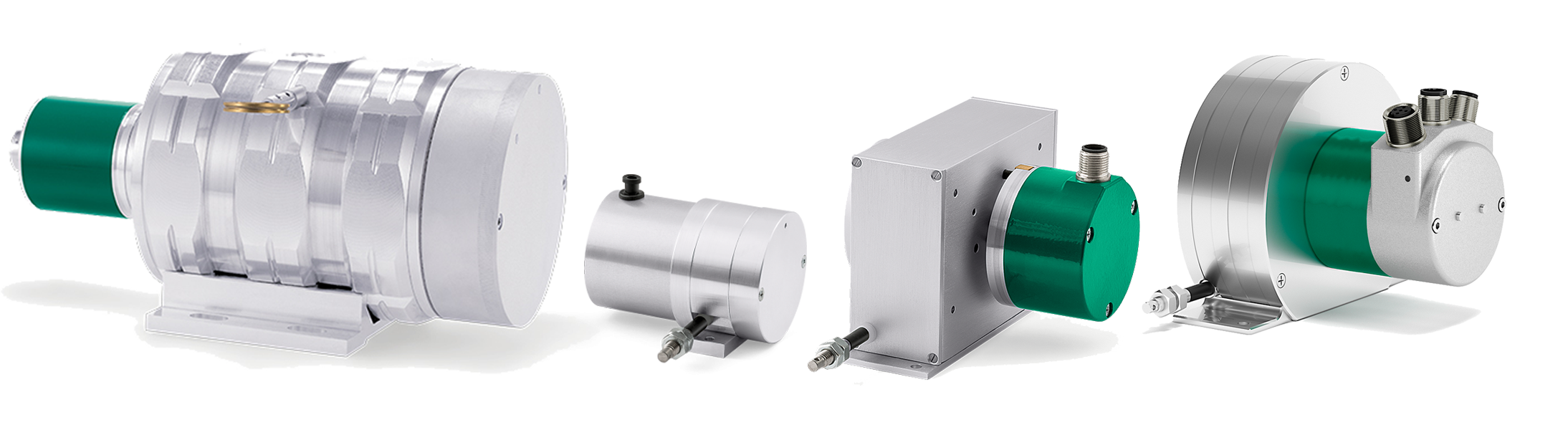

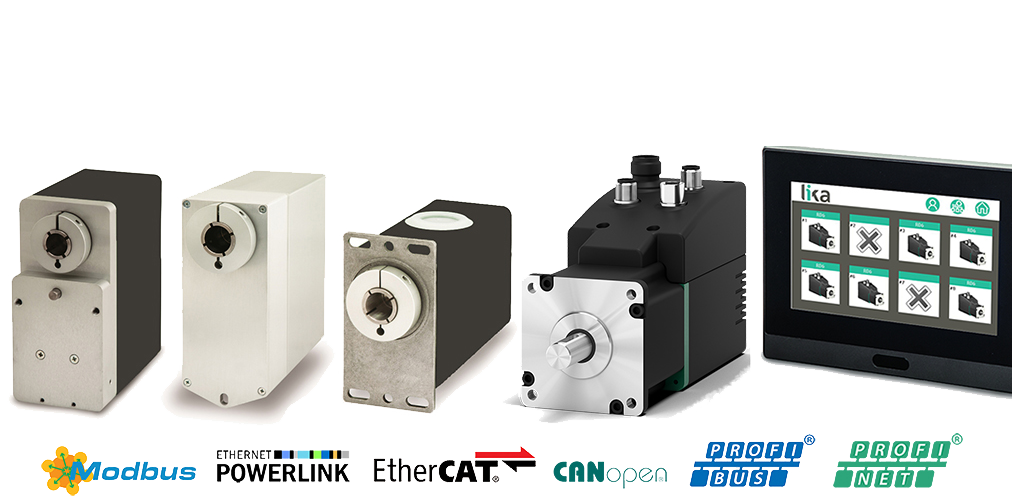

RD rotary actuators for changeovers and adjustment operations

Lika Electronic's RD rotary actuators are designed to automate changeovers and adjustment operations in auxiliary axes. Their configuration including brushless motor, real multiturn absolute encoder, position and torque closed-loop controller, and Ethernet / fieldbus interface eases and speeds up commissioning.

Available in four models and several power sizes.

• Designed to automate and ease changeovers and adjustments in auxiliary axes

• Four models with specific power rates and features

• All-in-one configuration for cost-effective integration

• Profinet, EtherNet/IP, EtherCAT, POWERLINK, CANopen, Profibus, MODBUS RTU interfaces

Among the typical application sectors of RD actuators are changeovers in packaging and bottling lines, adjustment operations in multiaxis systems, filling machines, mould changers, mobile stops, replacement of handwheels and position indicators, material handling equipment, bending machines, tool changers, spindle positioning devices, woodworking industry, plastic and paper industry, stone and metal processing industry.

Incremental and absolute linear encoders

Lika Electronic's incremental and absolute linear encoders combine a miniaturized and rugged design with contact-free and wear-free operation and ensure precise and reliable position and speed feedback in industrial applications and even in the harshest environments.

• Incremental and absolute range (including Ethernet interface options)

• Contact-, wear- and maintenance-free operation

• No moving parts, no mechanical stresses

• Robust design and up to IP69K protection

• Incremental measuring lengths virtually without limits, resolution down to 0.5 µm

• Absolute measuring lengths up to 19.3 m / 63.32 ft, resolution down to 0.29 µm

Lika's range includes a wide variety of linear encoders, as well as a number of solutions dedicated to custom applications such as encoders for toothed racks, encoders for UHV installations, and guided encoders.

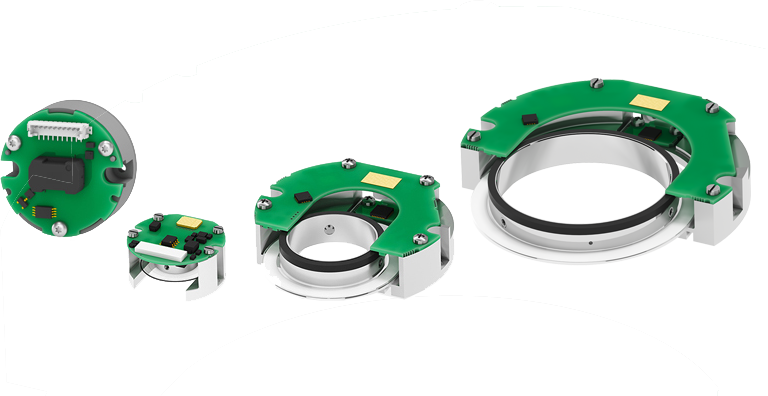

Explore our Range of Rotary Optical Kit Encoders!

Lika Electronic designs and manufactures a full line-up of rotary optical kit encoders for direct integration into robotic systems (for instance, surgical and diagnostic robots), cobots, robotic joints, servomotors, direct drive torque motors as well as into UAVs/drones, electromedical devices, and a variety of motion control systems.

They are designed in several sizes and shapes and offer a wide Xion of customizable specifications and technologies to fit special requirements. Kit encoders are frameless and bearingless and excel in compact size, low profile, minimum weight.

The optical technology allows them to achieve high resolution and fine accuracy for a very precise and safe control over movement, rotation, and positioning.

Contactless operation reduces machine downtimes and maintenance.

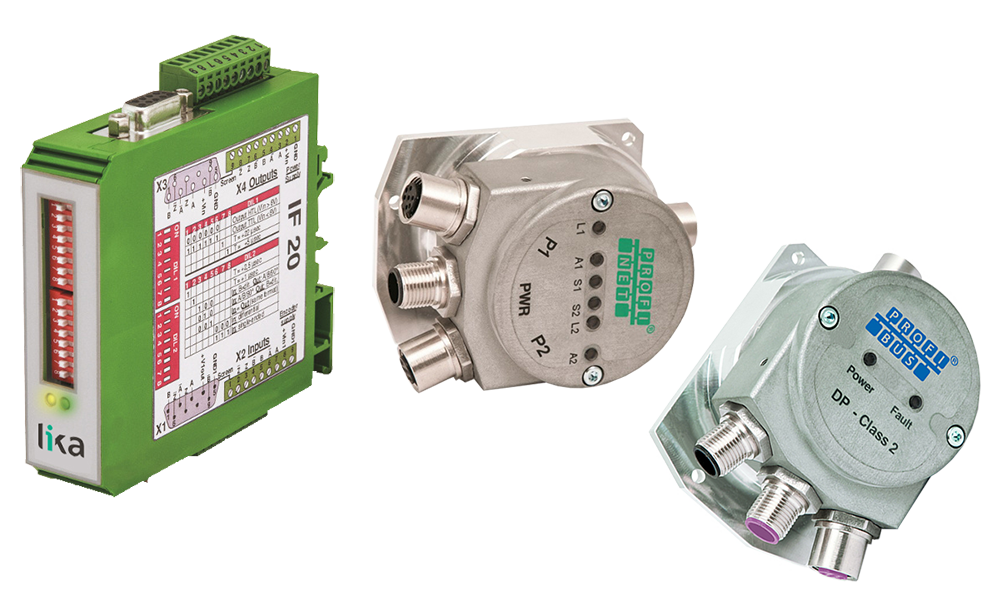

Converters and solutions for industrial integration and communication

Converters are often useful for adjusting the features of the encoder to the ones of the plant it must be installed on. Sometimes they are needful for retrofitting operations.

In many cases they allow also to upgrade and even add new functions to the encoder.

• Varied range of converters, interpolators, amplifiers, splitters, gateways, ...

• Designed for incremental and absolute encoders

• Designed for rotary and linear encoders

• Simple devices with basic functions

• Advanced devices with complete programmability and additional functions

For more information on the comprehensive range of interfaces and displays of the Posicontrol product family please download Lika's new catalog

Lika's range of couplings for standard and unique applications

Lika Electronic offers an extensive range of couplings suitable for a variety of automation sectors and in particular for encoders, general-purpose motors, servomotors, stepping motors, and actuators. They are available in several coupling designs (flexible, rigid, disc type, ...) and mechanical features (sizes, bore diameters, materials, treatments, ...) to accommodate different degrees of torque, misalignment, load, precision, and environmental work conditions.

The catalog also includes a rich Xion of couplings for special and unique applications.

Learn more on whole range

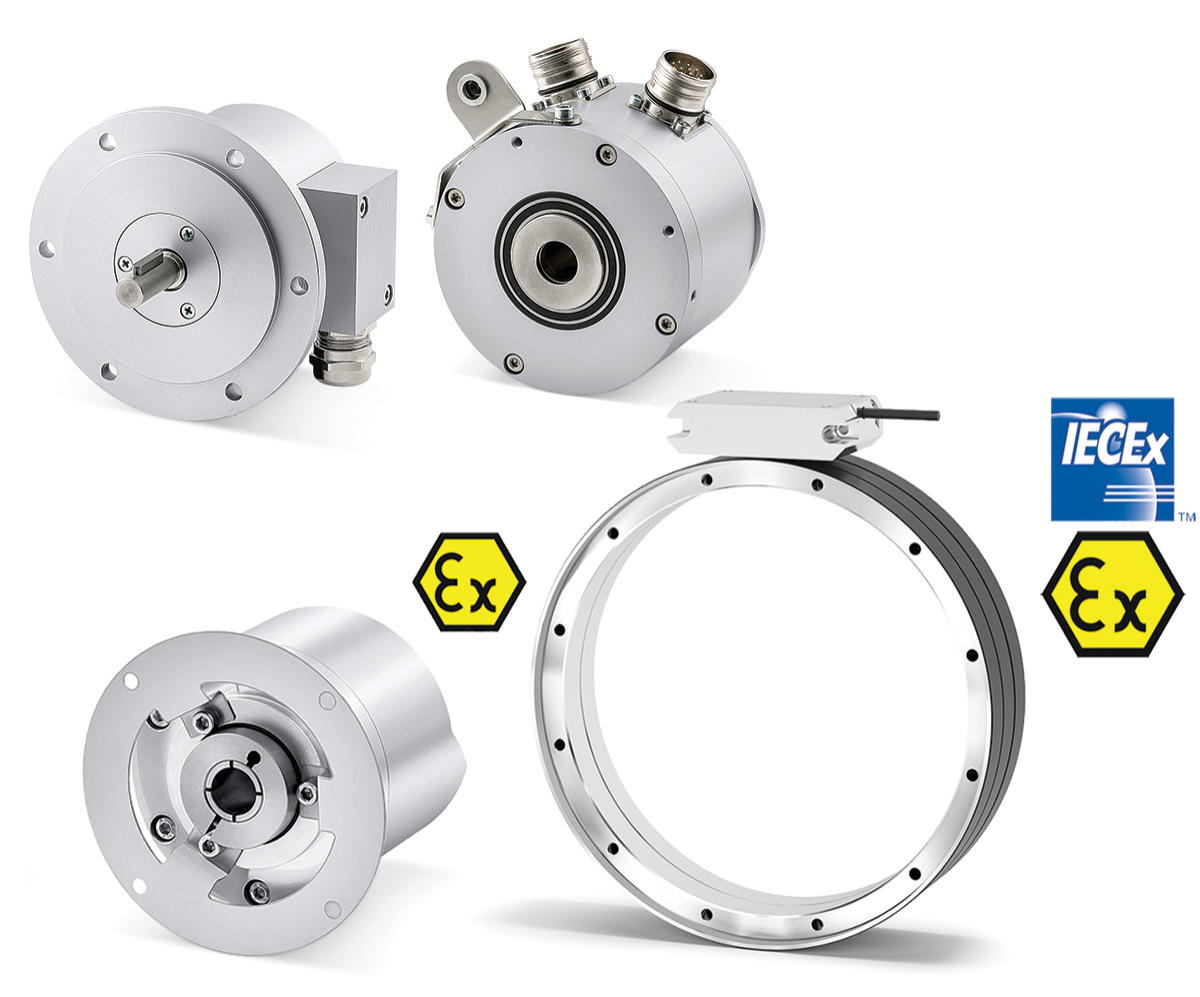

Heavy-Duty and ATEX encoders: rugged to deal with the roughest conditions

Harsh and hazardous environments require tough encoders with reliable and solid design, rugged mechanics, high reliability components, immunity to interferences, appropriate surface treatments and coatings, hermetically sealed housing.

The comprehensive range of heavy-duty and ATEX encoders is designed to cope with several

and different extreme conditions such as:

-

in oil and gas facilities

off-shore and marine installations

on/off-shore wind turbines

shipbuilding industry

heavy vehicles and construction machinery

mining industry

iron and steel mills

chemical plants

food industry

petrol refineries and laboratories

painting machines

fertilizer plants